Introduction

In the world of mechanical engineering and automotive design, the flywheel plays a crucial role in ensuring smooth operation and efficiency. One advanced concept that has garnered attention is the “flywheel 3 roue,” which represents a sophisticated approach to enhancing the performance of flywheels in various applications. This article delves into the intricacies of the flywheel 3 roue, exploring its functionality, benefits, and potential applications.

What is a Flywheel?

Before diving into the specifics of the flywheel 3 roue, it’s essential to understand the fundamental concept of a flywheel. A flywheel is a mechanical device used to store rotational energy. It consists of a heavy wheel or disc that spins around an axis, and its primary function is to smooth out the delivery of power from an engine or other rotating machinery.

Flywheels are commonly used in automotive engines, industrial machinery, and even in renewable energy systems. They help maintain consistent rotational speed, absorb fluctuations in power, and improve overall system stability.

Introducing the Flywheel 3 Roue

The flywheel 3 roue is a specialized design that incorporates three flywheels arranged in a specific configuration. The term “3 roue” translates to “three wheels” in French, indicating the unique design of this system. Unlike traditional single-flywheel setups, the flywheel 3roue aims to enhance energy storage, efficiency, and operational performance.

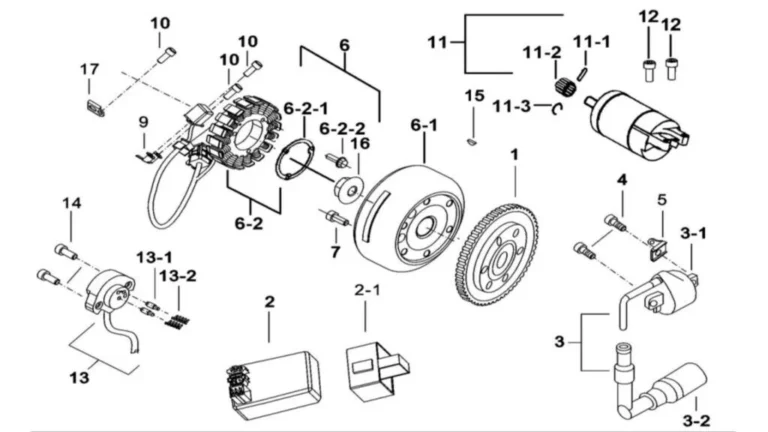

Design and Configuration

The flywheel 3 roue system features three flywheels mounted on a common shaft or axis. These flywheels are often arranged in a triangular or circular pattern, depending on the specific design and application. Each flywheel operates independently but contributes to the overall energy storage and management of the system.

The design of the flywheel 3roue is engineered to maximize rotational inertia and minimize energy loss. By distributing the load across multiple flywheels, this system can achieve higher efficiency and smoother operation compared to traditional single-flywheel designs.

How the Flywheel 3 Roue Works

The flywheel 3 roue system operates on the principle of rotational kinetic energy storage. As the flywheels spin, they accumulate rotational energy, which can be harnessed and utilized when needed. The three-flywheel configuration allows for more efficient energy storage and transfer compared to a single-flywheel system.

When power is applied to the flywheel 3roue, the three flywheels begin to spin, storing kinetic energy. This energy is then used to smooth out fluctuations in power delivery, improve system stability, and enhance overall performance. The distributed design of the flywheel 3roue helps reduce vibrations and increases the longevity of the system.

Advantages of the Flywheel 3 Roue

The flywheel 3 roue offers several advantages over traditional flywheel systems. These benefits make it a valuable solution in various applications, from automotive engineering to renewable energy systems.

Improved Energy Storage

One of the primary advantages of the flywheel 3roue is its enhanced energy storage capability. By incorporating three flywheels, the system can store more rotational energy compared to a single-flywheel setup. This increased energy storage capacity allows for better performance and efficiency in applications where consistent power delivery is critical.

Smoother Operation

The flywheel 3 roue design helps to smooth out fluctuations in power delivery. With multiple flywheels working in tandem, the system can better absorb and mitigate variations in rotational speed. This results in smoother operation and reduced vibrations, which can improve the overall performance and longevity of the equipment.

Increased Efficiency

The distributed design of the flywheel 3 roue contributes to increased efficiency. By reducing energy loss and improving energy transfer, the system can operate more efficiently compared to traditional flywheel setups. This increased efficiency can lead to cost savings and improved performance in various applications.

Enhanced System Longevity

The flywheel 3 roue’s design helps reduce wear and tear on the system. By distributing the load across multiple flywheels, the system experiences less stress and strain compared to single-flywheel designs. This can lead to increased longevity and reduced maintenance requirements, making the flywheel 3roue a reliable solution for demanding applications.

Applications of the Flywheel 3 Roue

The versatility of the flywheel 3 roue makes it suitable for a wide range of applications. From automotive engineering to industrial machinery, this advanced flywheel system can enhance performance and efficiency in various settings.

Automotive Engineering

In the automotive industry, the flywheel 3roue can be used to improve engine performance and efficiency. By incorporating multiple flywheels, automotive engineers can achieve smoother power delivery, reduce vibrations, and enhance overall engine performance. This can result in a more enjoyable driving experience and improved fuel efficiency.

Renewable Energy Systems

Renewable energy systems, such as wind and solar power, can benefit from the flywheel 3 roue’s energy storage capabilities. By using multiple flywheels to store and manage energy, these systems can achieve greater efficiency and reliability. The flywheel 3 roue can help smooth out fluctuations in energy production and improve the overall performance of renewable energy systems.

Industrial Machinery

In industrial machinery, the flywheel 3 roue can enhance the performance of various equipment, such as generators and pumps. The improved energy storage and efficiency provided by the flywheel 3roue can lead to better performance and reduced operational costs. Additionally, the smoother operation and increased system longevity can contribute to more reliable and efficient industrial machinery.

Challenges and Considerations

While the flywheel 3 roue offers numerous advantages, it is essential to consider potential challenges and limitations associated with this technology. Understanding these challenges can help ensure successful implementation and operation of the flywheel 3roue system.

Design Complexity

The design of the flywheel 3roue is more complex compared to traditional single-flywheel systems. Incorporating multiple flywheels requires careful engineering and precision to ensure optimal performance and efficiency. This increased complexity can result in higher design and manufacturing costs.

Maintenance Requirements

While the flywheel 3 roue can offer increased system longevity, it may also require more maintenance compared to simpler flywheel designs. Regular maintenance and monitoring are essential to ensure the proper functioning of the multiple flywheels and to address any potential issues that may arise.

Space and Weight Considerations

The flywheel 3 roue system requires additional space and weight compared to single-flywheel setups. This can be a consideration in applications where space and weight constraints are critical. Engineers and designers must carefully evaluate these factors when implementing the flywheel 3 oue system.

Future Developments

As technology continues to advance, the flywheel 3roue is likely to see further developments and improvements. Researchers and engineers are continually exploring new materials, designs, and technologies to enhance the performance and efficiency of flywheel systems.

Advances in Materials

Future developments may include the use of advanced materials to improve the performance and durability of the flywheel 3 roue. Lightweight and high-strength materials could reduce the weight of the system while maintaining or enhancing its energy storage capabilities.

Innovative Designs

Innovative designs and configurations may further optimize the flywheel 3roue system. Researchers are exploring new ways to arrange and integrate multiple flywheels to achieve even greater efficiency and performance.

Integration with Emerging Technologies

The flywheel 3 roue may also see integration with emerging technologies, such as advanced control systems and smart sensors. These integrations could provide real-time monitoring and optimization of the flywheel system, further enhancing its performance and efficiency.

Conclusion

The flywheel 3 roue represents a significant advancement in flywheel technology, offering enhanced energy storage, smoother operation, and increased efficiency. With its versatile applications in automotive engineering, renewable energy systems, and industrial machinery, the flywheel 3roue has the potential to revolutionize various fields.

While there are challenges and considerations associated with this technology, ongoing research and development are likely to address these issues and drive further improvements. As technology continues to evolve, the flywheel 3roue will remain at the forefront of innovation, providing valuable solutions for a wide range of applications.

Read more: Storecom FE AI: Smart AI Solutions for Modern E-Commerce